Contaminants in welding compromise the integrity of your work. Understanding the causes and utilizing the right methods for cleaning prevents defects from happening. This post breaks down how to avoid contamination to ensure a flawless welding process.

1. Clean Materials Thoroughly

Clean surfaces are essential for quality welding. Contaminants like grease or rust can negatively affect the weld joint.

The degreaser or acetone you use should be free of dust and moisture before beginning the weld. A properly cleaned surface is nonnegotiable for achieving top results in orbital or resistance welding projects.

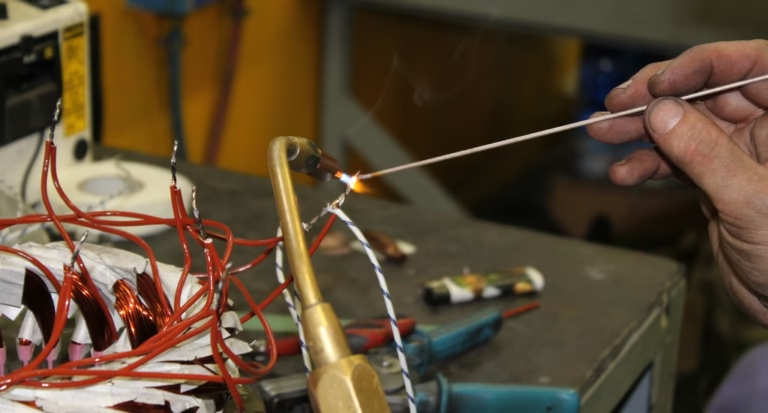

2. Handle Filler Materials Carefully

Filler materials can easily pick up contaminants if not handled properly. Keep them in sealed containers or protective packaging to prevent exposure.

Before use, make sure filler rods or wires are free of oxidation or other impurities.

3. Use High-Quality Shielding Gas

Shielding gas prevents atmospheric contamination by protecting the molten weld pool. Using poor quality or incorrect gas increases the risk of defects like porosity.

Using the right gas mix is one of the best practices to optimize orbital welding efficiency, while a premium shielding gas enhances quality and protection.

4. Proper Equipment Maintenance

Your equipment can harbor contaminants if not maintained regularly. Clean nozzles, torches, and electrodes to remove pollutants that can compromise your weld.

Inspect hoses for leaks, as even minor air seepage can introduce oxygen into the weld pool. Regular maintenance improves performance and reduces the likelihood of contamination during your projects.

5. Control Your Environment

The environment you weld in can heavily impact your results. Dusty, windy, or damp conditions can lead to problems. Whenever possible, weld in a controlled space, like a shop or designated job site, shielded from environmental factors.

If working outdoors, use welding blankets or shields to minimize exposure to contaminants. An optimal welding workspace is vital to achieving clean welds.

Welding With Confidence

Strong welding results depend on preparation and attention to cleanliness. Implementing measures like thorough material cleaning, effective shielding gas use, and consistent equipment maintenance will minimize the risk of irregularities. Complex resistance welding and its applications also benefit from effective maintenance, among most techniques.

Work with reliable tools and proven methods to avoid contamination in your welding processes. Clean processes lead to cleaner results every time.