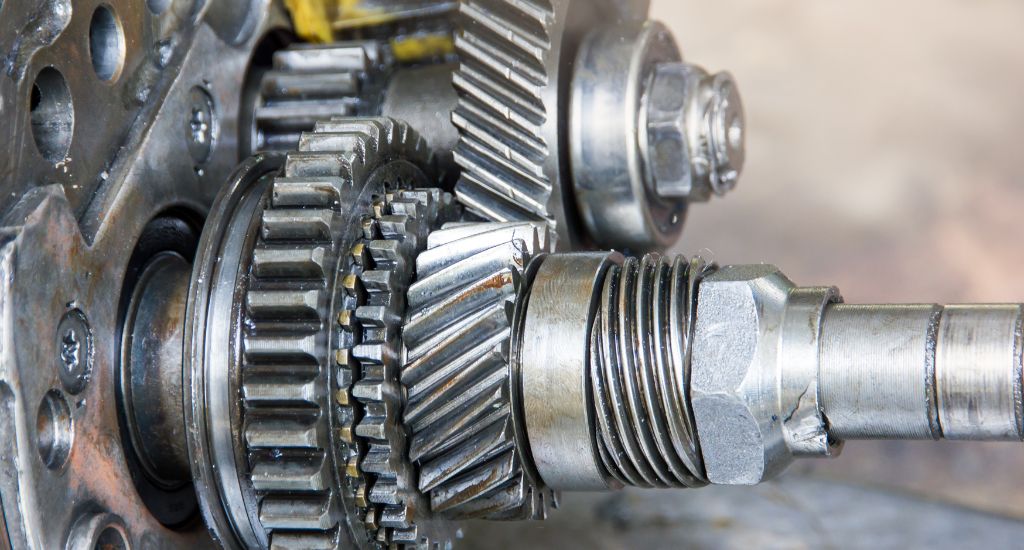

Whether you’re a seasoned engineer, an ambitious plant manager, a mechanical engineering student, or simply someone with a keen interest in how industrial machinery operates, understanding the critical role of gearboxes in the industrial sector is fundamental. Industrial gearboxes form the backbone of many manufacturing processes by transforming power into the precise form needed to efficiently drive production forward. Read on to learn about the three most important functions of industrial gearboxes.

Lower Speed Output of Power Source

One of the primary functions of industrial gearboxes is reducing the speed output from the power source to a level usable by the machinery they drive. This deceleration is crucial in manufacturing environments where precision and control over the speed of operations are vital for the quality of the final products. By modifying the output speed, gearboxes enable equipment to operate at optimal performance levels, maintaining the balance between efficiency and wear on machinery parts. This functionality enhances the longevity of the equipment and contributes significantly to energy conservation within industrial settings.

Increase Torque Delivered to Driven Equipment

Another fundamental role of industrial gearboxes is amplifying torque delivered to the driven equipment. This is particularly essential in industries where heavy loads must be moved, or significant force must be applied. Gearboxes adjust the mechanical power from the source to generate more torque with less speed, thereby allocating power more efficiently for heavy-duty operations. This increased torque capacity enables machinery to perform tasks that require high levels of force, such as lifting, moving, or compressing materials, with greater ease and precision.

Directional Control Over Operations

The third essential function of industrial gearboxes is providing directional control over operations. This capability allows the machinery to move in the desired direction and switch directions as necessary during the production process. The gearbox facilitates precise control over movement, whether that movement involves rotating a piece of equipment clockwise or counterclockwise or enabling complex machinery to perform intricate maneuvers. This level of control is indispensable for tasks requiring high precision and adaptability, ensuring operations are versatile and reliable. By offering directional control, industrial gearboxes significantly enhance the functionality and efficiency of the machinery they serve, making them indispensable in optimizing manufacturing processes.

Understanding the three important functions of industrial gearboxes ensures more efficient and successful industrial operations. But before you purchase a gearbox or related equipment for your plant, you must be sure to source materials from a reputable and quality power transmission equipment supplier. These distributors offer the most value for your investment and guarantee a higher level of performance. They can also assist with general power transmission concerns, such as helping you determine the ideal time for conveyor belt maintenance or bearing replacement.