There is some basic mechanical equipment that one can use to compress the gas or air just to operate and they are known as pneumatic tools. You can also call them air pressure tools and use them for various purposes. It will save a lot of time and energy but if you are not professional enough then you will not be able to handle them as it needs some special handling and care. The Pneumatic products are top-notch tools that will make your living easier.

You can use these tools for a lot of purposes as there are different types of air pressure instruments you will get in the market. Some very common instruments are nail guns, staple guns, buffers, paint sprayers, grinders, jackhammers, chipping hammers, wrenches, reverting guns, and others. Apart from that, air-powered equipment can be used for several purposes.

Types & its Usage

1. Blowguns

Blowguns are quite popular for their usage. You can use them for blowing dirt and dust away from the surfaces.

2. Nail Guns

These nail guns are popular for some basic reasons. You can call them an air hammer or the power nailer as well. They are much more efficient and of course, powerful than the manual process of hammering the nails. You can use them for several purposes such as scrapping, cutting, and chipping as well.

3. Air Sanders

They are very useful in order to remove paint and rust and they will make your automotive work more efficient.

4. Air Staplers

If you are finding a great way to make your stapling faster then you should try out this for an efficient and perfect outcome.

5. Caulking Guns

These will produce uniform beads in order to apply the surface at a quick pace.

Both of the air drills and tapping machines are making use of the compressed air in such particular pneumatic tools for extremely efficient functioning. However, the Pneumatic products manufacturer in India is constantly putting their best to make these tools more efficient.

Advantages Of Pneumatic Tools

Some advantages you should know while choosing these tools.

- These tools weigh less and the power is transferred through the air compressor. It eventually makes the usage easier.

- It is absolutely not the same as the manually operated tools rather these are more efficient and powerful.

These Pneumatic products are cost-effective which are ideal for the application of slurries or liquids containing a significant amount of sustaining solids. They are sealed by using one or more flexible elements like rubber tubes that become pinched to turn off the flow. The process plants consist of hundreds and thousands of controlled loops all networked together to produce the products which offer for sale.

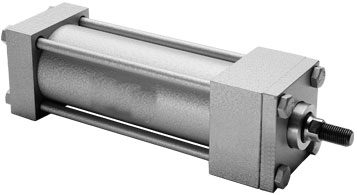

The popular style of a cylinder consists of a piston and rod moving inside the closed cylinder. This can be sub-divided into two types based on the operating principle: single acting and double acting. A single-acting cylinder uses one airport to allow the compressed air to the cylinder to move to the piston to the desired position and then return back to the original position.